Welcome to Wilh. Schäfer GmbH

For three generations, Wilh. Schäfer GmbH has stood for the highest precision in metal processing. As experts in the Frankfurt/Rhine-Main region, we are your partner for sophisticated CNC machining, contract manufacturing, and complex prototype construction. From individual components to series production – we bring your visions to life using state-of-the-art technology.

Are you looking for a partner who can turn your ambitious product ideas into reality? Someone who doesn’t just manufacture, but thinks ahead and finds innovative solutions for your unique requirements? Then you’ve come to the right place!

From the initial concept and prototyping to small-batch production: We are your professional partner for contract manufacturing, prototype construction, and fixture construction.

Our Expertise:

🔹 CNC Manufacturing with Power

🔹 Turning, Milling, Turn-Mill and 5-Axis Machining

🔹 Prototyping that makes ideas tangible

🔹 Small-batch production that runs smoothly

🔹 Machining of high-performance and challenging materials

Manufacturing for diverse industrial sectors:

🔸 Mechanical and Fixture Engineering 🔸 Automotive

🔸 Aerospace 🔸 Die and Mold

🔸 Control and Instrumentation 🔸 Food Industry

🔸 Petrochemicals 🔸 Medical Technology

🔸 Audio Media Industry

Milling

Moving more than just chips! Precision in every dimension: Our 5-axis machining centers deliver complex components with unrivaled accuracy.

Turning

Mastering the turn! High-quality cylindrical components manufactured on the latest lathes and turn-mill machining centers.

Design for Manufacturing (DfM)

Cost-efficiency begins in the design phase. By focusing on Design for Manufacturing (DfM), we help you optimize your components for production. Our experts analyze your designs for feasibility, cost drivers, and material efficiency.

The goal: Shorter lead times in CNC milling and turning, reduced material waste, and a significant reduction in production costs – without compromising on quality.

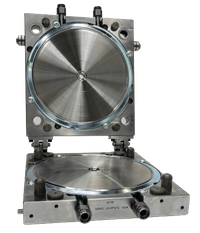

Vinyl Production

Bringing sound to life!

As a global partner to the music industry, we ensure production in vinyl pressing plants worldwide with our high-precision spare parts. This extensive experience in global logistics and the absolute precision of our components guarantee maximum reliability and on-time delivery for our CNC contract manufacturing customers as well.

FAQ

Which materials can be processed?

We process the entire spectrum: from aluminum and stainless steel (AISI 304/316) to tool steel, non-ferrous metals, and technical plastics (POM, PEEK).

Can you manufacture complex 5-axis components?

Yes, our machinery is specifically designed for high-precision 5-axis simultaneous machining. This allows us to manufacture the most complex geometries with a minimal number of setups.

What does “Design for Manufacturing” (DfM) mean at Wilh. Schäfer?

We think ahead. We review your CAD data for manufacturability and actively advise you if we identify potential for production cost optimization.

Which file formats are required for an inquiry?

STEP files are ideal. For the final inspection and tolerance specifications, we also require a technical drawing in PDF format.

Why does a CNC company manufacture tools for the music industry?

It is part of our history. Having started as a contract manufacturer, we now distribute these as our own specialized products. The extreme requirements for precision and surface finish in vinyl press molds are in our DNA. We apply this “zero-defect mentality” to every project in general mechanical engineering.

Do you produce records yourself?

No, we are purely a mechanical engineering company. We manufacture the highly specialized precision tools (press molds, die clamping rings, etc.) used in pressing plants worldwide.

Do “regular” mechanical engineering customers benefit from this expertise?

Absolutely. Mastering the tolerances required for the global vinyl market brings a level of diligence that ensures the highest quality even for standard components.

What batch sizes do you manufacture?

We specialize in individual parts, prototypes, and small to medium-sized series (approx. 1 to 500 units).

How quickly will I receive a quote?

If STEP files are provided, you will typically receive feedback or a complete quote from us within 24 to 48 hours.

Do you deliver to international customers?

Yes. We are experienced in global shipping and handle secure packaging as well as all necessary customs documentation.

Are you available for small local orders?

Definitely. Despite our international customer base, we remain true to our roots in Bad Homburg and serve regional partners with the same level of care.